|

|

|

[Sponsors] | |||||

|

|

|

#1 |

|

New Member

Join Date: Aug 2012

Posts: 20

Rep Power: 14  |

Hello CFX Community,

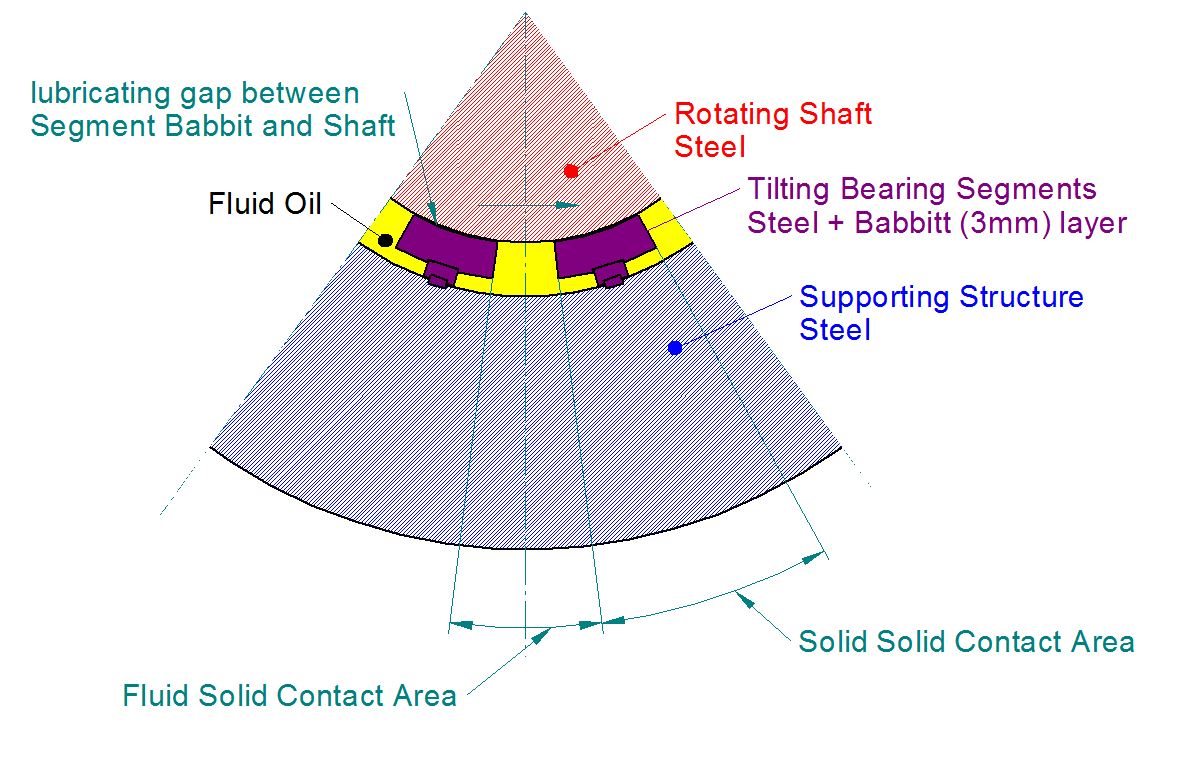

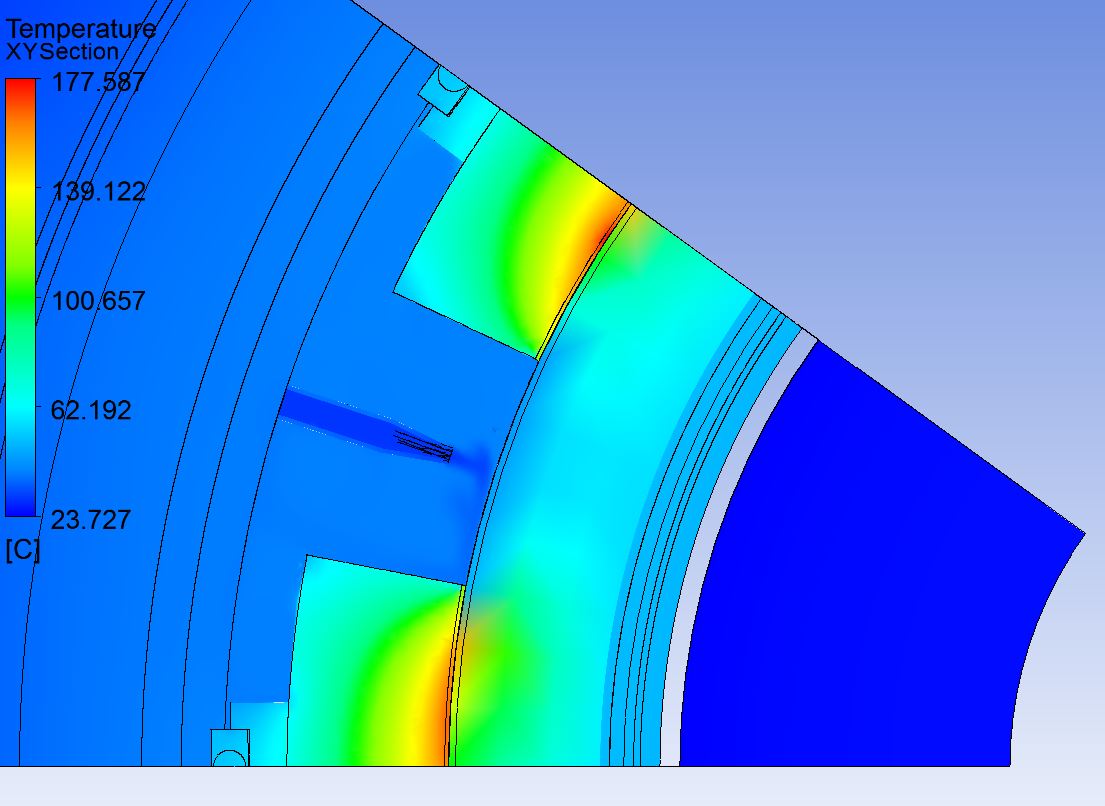

At the moment i am dealing with a simulation of a bearing. The Bearing type is a radial one, with 10 pieces of tilting segments. the goal of this analysis is not to solve the lubricating of the bearing itself. The goal is to get a temperature distribution for the whole bearing (Fulid and Solid). Please find a picture below which shows the problem:  In the middle (red) there the rotating shaft made out of steel. The purple elements are the radial bearing segments which consist out of steel plus a thin layer ot a bearing babbit. The forces from the Segments will be transfared to the supporting structure which is also made out of steel. I want to calculate the temperature distribution to see how the bearing gap changes while heating up (done by steady state analysis.) The Fluid oil can be found shaded with yellow color. The lubricating gap itself is not considered in my calculation model. I am applying the calculated friction losses between the segments and the shaft as a source (calculated by a different program). So far to the boundaries, my problem or question is the following: I modeled a sector of the bearing similar to the picture shown above. The cylindrical shaft surface was split on the circumferene so that i can get a surface where the segment is in contact with the shaft and the fluid is in contact with the shaft. In reality it the same sufrace but i split it to can have to different interfaces (Solid/Solid, Fluid/Solid). At least for my problem there is no stage interface available. It is only possible to select Frozen Rotor. The Result of the current Simulation is the following:  The heat is only tranfered to the shaft at the region where the frozen rotor interface is located. In reality the shaft it turning and so the shaft will heat up equally due the rotation of it. How can i consider this phenomena? Do i need to run this simulation transient? but at least then i think i cant apply a split at the bearing surface. Would simulating the lubricating film help me to have just 1 Interface? How can i consider the heat which is created by the oil due to shear stress? I also want to consieder the losses which are created in the space between the segments due to the contact of the fluid with the shaft. The material properties ot the oil are temperature dependend and bouyancy is also considered. Do i need to use Thermal Energy or Total energy? I read the help and Total energy considers "Kinetic Energy". My fluid is moving so do i have to use total energy? Thank you very much in advance for helping me out... m0h |

|

|

|

|

|

|

|

|

#3 |

|

Super Moderator

Glenn Horrocks

Join Date: Mar 2009

Location: Sydney, Australia

Posts: 17,870

Rep Power: 144     |

This model looks like it requires convection of heat in a solid due to a movement of the solid. You need CFX V15 to do this, earlier versions do not support it.

Try using solid domain motion with a rotation on the inner solid domain. |

|

|

|

|

|

|

|

|

#4 |

|

New Member

Join Date: Aug 2012

Posts: 20

Rep Power: 14  |

Hello all,

thanks for the fast reply. At least i can see the pictures and it seems that ghorrocks can see it too ... does the problem still exist diamondx? Regards m0h |

|

|

|

|

|

|

|

|

#5 |

|

New Member

Join Date: Aug 2012

Posts: 20

Rep Power: 14  |

Hey all,

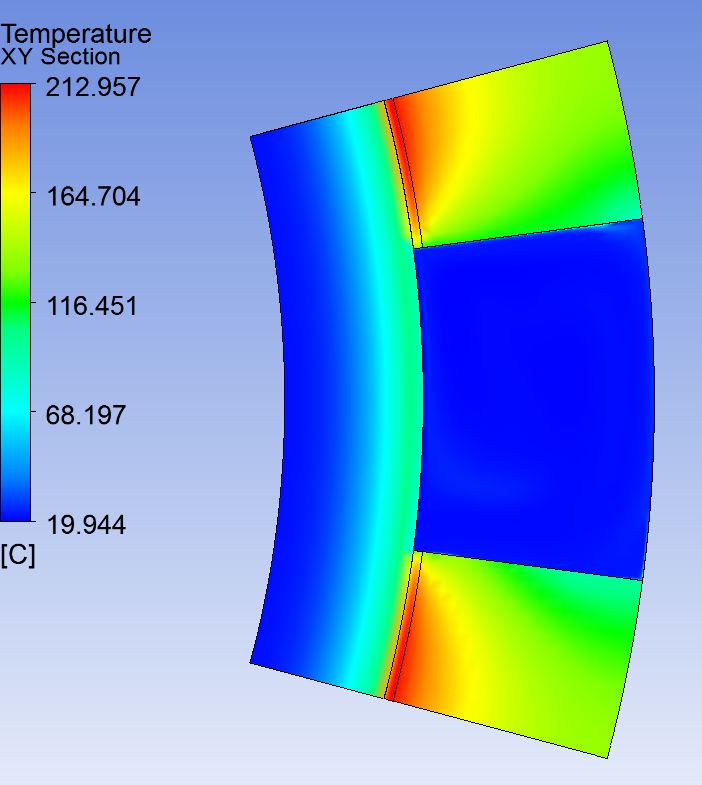

ghorrocks, I just wanted to say thank you for supporting all these guys in this forum and also me, thank you very much. your hint brought me to success  . .I did a simplified model to test it.  As you can see, the temperature distribution on the shaft is nearly equal if you observe the circumferential distribution. so solve this problem it was necessary to split the shaft cylinder in several faces because its not possible to select 2 times the same surface for an interface. Furthermore my mistake was to select "domain motion" for the shaft (solid). You have to enter the solid tab and use "Solid Motion" and set domain motion to stationary. If you do that, an warning appears which recommends you to define a wall motion in the fluid domain at the interface to the shaft. Regards, m0h |

|

|

|

|

|

|

| Tags |

| cfx, interface, thermal analysis |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Cluster ID's not contiguous in compute-nodes domain. ??? | Shogan | FLUENT | 1 | May 28, 2014 16:03 |

| Simulation of varying contact angles for a large droplet of water on a surface | cp703 | CFX | 5 | July 20, 2013 07:08 |

| Multiple domain interfaces on a single surface | mike | CFX | 2 | January 26, 2009 18:03 |

| Patran Volume Meshing | Deb | CFX | 19 | April 17, 2003 11:56 |

| free convection heat transfer from a heated horizontal surface through a liquid to a thin cooled fin | Kaushik | FLUENT | 1 | May 8, 2000 07:47 |