|

|

|

[Sponsors] | |||||

|

|

|

#1 |

|

New Member

wendy

Join Date: Jul 2013

Posts: 8

Rep Power: 13  |

This question about General Momentum Source has puzzled me for several days. I hope some one can give help to me. Thanks.

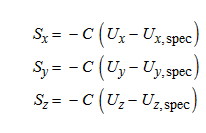

In the documention, about the General Momentum Source: The General Momentum Source option is useful for applications that are not covered by the isotropic loss model or the directional loss model. For example, the velocity in a region may be forced to be a specified value (Dirichlet velocity condition) by setting C to a large number, for example, 10^5 kg m-3 s-1, for the following:  I have two questions: 1. What are the Ux and Ux,spec represent? Ux is the speed at present and Ux,spec is the speed I want set? By this way, I can set the Ux to speed Ux,spec, right? 2. If there are air and water in my domain, and I want set the speed of water with temperature under 273K to zero, are the following settings right? Sx=-C*(u-0) Sy=-C*(v-0) Sz=-C*(w-0) C=step(273-Water.T)*Water.vf*10^6 Thanks |

|

|

|

|

|

|

|

|

#2 |

|

Senior Member

Matthias Voß

Join Date: Mar 2009

Location: Berlin, Germany

Posts: 449

Rep Power: 20  |

This is correct. Keep an eye on the derivatives of your expression w.r.t. u/v/w . Check out the help on this, there is an suggestion for the scalar-lin. Coefficient to help it converge better.

Edit: if you´re using euler-euler formulation (inhomogeneous) you can use Water.Velocity uvw instead and sepp. the phases. Which should be a better idea anyway since you cannot have the air moving and at the same time resting the water via. the momentum source @ the interface (alpha = 0.5). |

|

|

|

|

|

|

|

|

#3 |

|

New Member

wendy

Join Date: Jul 2013

Posts: 8

Rep Power: 13  |

Dear mvoss, many thanks for your kind help.

Actually, I am model the welding process. The steel (Q235) undergoes melting and solidification under the heating arc and, at the same time molten steel drop into the molten pool. I want to know the shape of welding bead and it is regarding two phase (air and liquid), free surface, and heating problem.  First, I model the steel as a liquid. There are steel and air in the domain. After adding a volumetric heating source onto the steel, there can get a right temperature field. Then, I add General Momentum Source as following to force the steel under temperature 1753K to a velocity of 0. But this time, the temperature is not right after 0.7s. Sx=C*step(1753-Q235.T/1[K])(Q235.velocity u-0) Sy=C*step(1753-Q235.T/1[K])(Q235.velocity v-0) Sz=C*step(1753-Q235.T/1[K])(Q235.velocity w-0) C=-10^7 And I add a Continue source of Q235 to model molten steel drop into the molten pool. It is named Rongdi. This model did not even converge. I have enclosed the .def documents, and please give some suggestion for me. filedownload Last edited by cqlwj123; July 22, 2013 at 10:31. |

|

|

|

|

|

|

|

|

#4 |

|

Senior Member

Matthias Voß

Join Date: Mar 2009

Location: Berlin, Germany

Posts: 449

Rep Power: 20  |

Why is it always

Sy=C*step(1753-Q235.T/1[K])(Q235.velocity u-0) ? You should use the correct components for the source. What do you mean by: "And I add a Continue source of Q235 to model molten steel drop into the molten pool. It is named Rongdi. This model did not even converge." If you are trying to model TIG welding or similar check out the research from TU DRESDEN These are the most advanced afaik. I cannot be of any real help at this point, to long ago for me.

|

|

|

|

|

|

|

|

|

#5 |

|

New Member

Ganesh K C

Join Date: Oct 2014

Location: Tiruchirappalli, India

Posts: 29

Rep Power: 12  |

how to calculate the lorentz force source terms in tig welding ?

|

|

|

|

|

|

|

|

|

#6 |

|

Senior Member

Davide

Join Date: Jul 2015

Posts: 107

Rep Power: 11  |

At the end have you solved your problem? I'm also intereseted to use a general momentum source to set zero the velocity of the glass in a VOF model. In the menu of the subdomain is required to set the X,Y,X component in [kg/(m^2*s^2)]: what value must I set to have a velocity of the glass zero? Then momentum source coefficient? Is then necessary specify for the momentum source coefficient an expression to make this coeffcient high only for glass.Vof>0?

|

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| momentum source term | zwdi | FLUENT | 14 | June 27, 2017 16:40 |

| Need help defining a momentum source for a diffuser inlet | serezhkin | CFX | 1 | April 2, 2013 13:20 |

| Version 15 on Mac OS X | gschaider | OpenFOAM Installation | 113 | December 2, 2009 11:23 |

| [Gmsh] Compiling gmshFoam with OpenFOAM-1.5 | BlGene | OpenFOAM Meshing & Mesh Conversion | 10 | August 6, 2009 05:26 |

| Pressure jump and momentum source | Tanya | FLUENT | 1 | June 4, 2009 16:22 |