|

|

|

[Sponsors] | |||||

Dynamic meshing problem: How to realize compression process of oil film in Fluent? |

|

|

|

LinkBack | Thread Tools | Search this Thread | Display Modes |

|

|

|

#1 |

|

New Member

Join Date: Feb 2020

Posts: 28

Rep Power: 6  |

Hello, everyone:

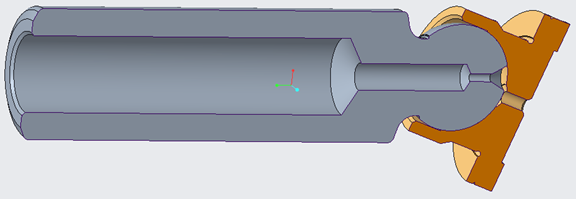

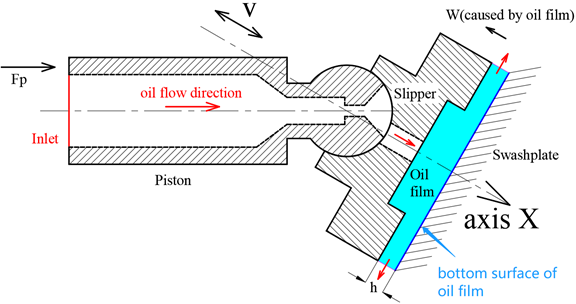

I want to realize compression process of oil film in Fluent, the case comes from oil film between slipper and swashplate in a pump, Figure 1 presents piston and slipper in 3D model, Diagram 1 shows the relationship of piston, slipper and oil film. Basic rationale of how this film works is as follows: Oil pressure acting on surface of piston left side causes force Fp, film height h and counterforce W produced by film varies with Fp, for example, with increase of Fp, slipper will move along axis x in positive direction, then oil film will be squeezed, as a result, heigh h decreases, and at the same time, force W increases to a certain value to make slipper reaches new equilibrium position. What I want to realize is: Set the oil pressure in inlet as input(Figure 2 shows the expected setting pressure), the bottom surface of oil film moves along the axis x, then I can see how oil film height h and force W changes, I guess this involves with dynamic mesh and UDF, but I am not sure if my assumption is right(if it is true, how to do?), or is it possible to realize this simulation in Fluent? P.s. In the past, I had also done cases involves dynamic mesh, but at that time, I knew the exact motion function, so I could write the velocity expression of moving wall in UDF codes, but at this time, I just know the inlet pressure and I donít have function between Fp and the velocity of bottom surface of oil film(assuming the bottom surface of oil film as moving wall instead of fluid domain of piston and slipper), i.e. v=f(Fp), thus, I donít know how to deal with this situation.  Figure 1-a  Figue 1-b  Diagram 1  Figure 2 Regards, Silence |

|

|

|

|

|

|

| Tags |

| dynamic mesh technology, fluent. cfd, lubrication, pump simulation, udf code |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| [Gmsh] gmshToFoam generates patches with 0 faces and 0 points | Simurgh | OpenFOAM Meshing & Mesh Conversion | 4 | August 25, 2023 08:58 |

| SU2-7.0.1 on ubuntu 18.04 | hyunko | SU2 Installation | 7 | March 16, 2020 05:37 |

| [Gmsh] Vertex numbering is dense | KateEisenhower | OpenFOAM Meshing & Mesh Conversion | 7 | August 3, 2015 11:49 |

| The fluent stopped and errors with "Emergency: received SIGHUP signal" | yuyuxuan | FLUENT | 0 | December 3, 2013 23:56 |

| Gambit Meshing export to fluent minor problem | John c. | FLUENT | 2 | February 6, 2002 17:52 |