|

|

|

[Sponsors] | |||||

|

|

|

#1 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

Hi there,

Software Used: Fluent, Mesh Generator: Gambit I am simulating a flow in a turbine cascade. Please find my geometry in the attached picture. My inlet velocity is 1.05m/s and Re = 72000. I am using the SST k-w model. My chord length is 1m. As per the model and other settings, transition happens at 0.2 m into the blade on the suction side i.e. the lower blade in the geometry. However, transition is expected to be between 0.4 and 0.6. Please suggest some ideas for the above problem. |

|

|

|

|

|

|

|

|

#3 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

It feels this forum is just dead! No point putting questions up here nymore!

|

|

|

|

|

|

|

|

|

#4 |

|

Senior Member

|

What is the problem exactly? You just said you are solving problem involving transition and you are expecting is at 0.2 m location ! 0.2 m from leading edge along the axial chord or on the suction side?

Some more details are required like : 1. How many no of nodes you are using. What is overall mesh? How many nodes you are using in the transition region? 2. What is your Yplus? 3. What are the turbulence parameters at inlet and are the same as per experimental set-up? |

|

|

|

|

|

|

|

|

#5 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

Thanks for coming forward to help me out. My problem is that I am not able to get the correct transition point as per the journal I am referring to.

For an intensity of 2.8%, my transition point is at 0.6m into the blade on the suction side (lower edge in my geometry). So for a higher intensity i.e. 8.4%, I am expecting the transition point to be between 0.4 and 0.5. I am basing this understanding on Wissink's "Direct Numerical Simulation of flow and heat transfer in a turbine cascade with incoming wakes"-page 231 (Nu Graph). Can you suggest some changes in my setting or give me other ideas? Please find my geometry and Nu plot in the attached pictures. My inlet velocity is 1.05m/s and Re = 72000. My chord length is 1m. Software Used: Fluent, Mesh Generator: Gambit Following are my settings: 1. Refined mesh at the edges to predict accurate boundary layer. y+ is <1 2. I am using the Transition SST-4 equation model with Viscous heating and curvature correction on. Apart from that Model constants are default values 3. I am aiming for an intensity of 8.4% so inlet conditions are set to Intermittancy as 0.64, Intensity 8.4 and length scale as 1 (based on my chord length). Other settings are "Third-Order Muscle" and "Power law" for Spatial Discretization section in Fluent. My monitors except for continuity are all set to 1e-06. |

|

|

|

|

|

|

|

|

#6 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

I can send you my case and data files if that works and can help me out quicker.

|

|

|

|

|

|

|

|

|

#7 |

|

Senior Member

|

There are many suggestion I can give you to refine your case:

1. It is possible that at higher turbulence intensity there is fully turbulent flow. 2. Don't confuse wakes with turbulence intesnity. Wakes are something trasient flow phenomena and occurs periodically when downstream blade is moving at certain rpm. 3. To have wake effect, you can implement trasient gaussian profile or do the precursor simulation of upstream wakes by just modelling a suitable diameter cylinder. 4. The point where you are expecting transition, mesh should be refined with 20-30 nodes in the vicinity of that location. 5. You should plot mean CP as CP is changing from time step to time step. For this you have turn-on time statistics data sampling after the simulation has achieved periodic convergence. 6. Divide blade into to parts. Which you already have pressure and suction sides. Specify them separately in boundary conditions in gambit. When you plot Cp you will observe there is option of data write. Write data sepratly using the option curve length. 7. Open these files in excel and divide each dimension (curve length) by maximum value. In this way you will normalize curve length between 0 and 1 and now you have suction and pressure side on the same scale otherwise they had different lengths. 7. Did you calculate boundary layer thickness through laminar or turbulent flat plate formula to estimate the boundary layer thickness in your case. 8. Are you using second order schemes for all variables including turbulence. 9. Are you using coupled or piso scheme along with second order implicit time scheme? PS: Send your reference paper, case and data files. |

|

|

|

|

|

|

|

|

#8 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

Thanks for all the suggestions. I have sent the reference paper, case and data files on turboenginner@gmail.com

1.It is possible that at higher turbulence intensity there is fully turbulent flow. A1. On pressure side I believe it must be fully laminar looking at the velocity contour plot. IS there a method to tell at which point on the blade the flow becomes turbulent?? 2. Don't confuse wakes with turbulence intesnity. Wakes are something trasient flow phenomena and occurs periodically when downstream blade is moving at certain rpm. A2. I understand the difference between wakes and intensity. Its just that I was asked to simulate the cascade model without wakes in 2D RANS and was just asked to match the intensity at the measurement point. i.e 0.2m in front of the blade. (page 215-Wissink's Journal) 3. To have wake effect, you can implement trasient gaussian profile or do the precursor simulation of upstream wakes by just modelling a suitable diameter cylinder. A3. Thanks for this suggestion, I can mention it in my further work. 4. The point where you are expecting transition, mesh should be refined with 20-30 nodes in the vicinity of that location. A4. I believe the mesh is well refined at the edges but do I have to refine it in the section between the blades as well? Since it is left coarse in the journal as well. 5. You should plot mean CP as CP is changing from time step to time step. For this you have turn-on time statistics data sampling after the simulation has achieved periodic convergence. A5. Is periodic convergence applicable for RANS? If in case of RANS, do u mean plot Cp on Suction and Pressure Side using the dropdown options in Fluent. I get a fish shaped graph but not as exact as Wissink's Journal. 6. Divide blade into to parts. Which you already have pressure and suction sides. Specify them separately in boundary conditions in gambit. When you plot Cp you will observe there is option of data write. Write data sepratly using the option curve length. A6. Already done that as you can see S/So on my Nu Graph added above in this discussion 7. Open these files in excel and divide each dimension (curve length) by maximum value. In this way you will normalize curve length between 0 and 1 and now you have suction and pressure side on the same scale otherwise they had different lengths. A7. Already done that. 7. Did you calculate boundary layer thickness through laminar or turbulent flat plate formula to estimate the boundary layer thickness in your case. A8. Is it using this formula: Delta = 0.382*x/Re_x ^ (1/5)? 8. Are you using second order schemes for all variables including turbulence. A9. I have tried running basic simulation (Default parameters) using SIMPLEC, PISO and COUPLED while using Second Order or Third Order for Spatial Discretization. However for SST-Transition model.. only SIMPLEC with Third Order Muscle gives reasonable results. 9. Are you using coupled or piso scheme along with second order implicit time scheme? A10. I haven't seen second order implicit scheme for RANS. |

|

|

|

|

|

|

|

|

#9 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

Nd its dead again! Anyone there with useful suggestions?

|

|

|

|

|

|

|

|

|

#11 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

Hi Far,

Have u looked at my email, case and data files yet? I cannot improve my mesh in Gambit anymore coz I am running out of time. If possible can you answer the questions I have above (That long blue and black reply) Thanks |

|

|

|

|

|

|

|

|

#12 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

Improved the mesh and the boundary layer, used the same settings as mentioned above or as seen in my case and data files. Still No change in the results.

If possible can I request you to answer some of my doubts raised above. Any help with be appreciated. Thanks |

|

|

|

|

|

|

|

|

#13 |

|

Senior Member

|

pls see this thread: http://www.cfd-online.com/Forums/flu...imulation.html

|

|

|

|

|

|

|

|

|

#14 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

Hi Far, if possible can you please email me your case and data files for your study in Transition SST model? I would like to have a look at your settings in detail to understand if I can incorporate some of them into my model.

As I am studying my model in steady state solver, it appears to be quiet hard to get a stable solution. |

|

|

|

|

|

|

|

|

#16 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

its ......

Thanks in advance. Last edited by aditipatel7; April 17, 2013 at 23:06. |

|

|

|

|

|

|

|

|

#17 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

ok I just have one basic question here...

How can you tell at which point the flow transitioned from laminar to turbulent? I know we can do u+ vs y+ for a flat plat boundary layer profile. But for an airfoil that is curved...what is the method? Last edited by aditipatel7; April 17, 2013 at 23:39. |

|

|

|

|

|

|

|

|

#18 |

|

New Member

CFD User

Join Date: Feb 2012

Posts: 18

Rep Power: 14  |

ok I just have one basic question here...

How can you tell at which point the flow transitioned from laminar to turbulent? I know we can do u+ vs y+ for a flat plat boundary layer profile. But for an airfoil that is curved...what is the method? |

|

|

|

|

|

|

|

|

#19 |

|

Senior Member

|

Hmmm. there are many methods to do this...

1. Plot intermittency 2. Plot integral parameters (e.g shape factor) There may be other methods to do this. You need to explorer relevant journal research papers to see how people have decided about the two regions and how they infer transition from other flow variables. |

|

|

|

|

|

|

|

|

#20 |

|

Member

venkatesh

Join Date: May 2012

Posts: 93

Rep Power: 14  |

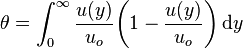

I am analyzing transition point over NACA 4412 airfoil at low Reynolds number using Transition Kw-SST model. I am using FLUENT for simulation. I dont know how to plot Shape factor from FLUENT result. I know that Shape factor can be calculated using the relation

where H is the shape factor, where H is the shape factor,  is the displacement thickness and θ is the momentum thickness.The definition of displacement thickness, δ for incompressible flow is is the displacement thickness and θ is the momentum thickness.The definition of displacement thickness, δ for incompressible flow is Where Where  and and  are the density and velocity in the 'free stream' outside the boundary layer, and are the density and velocity in the 'free stream' outside the boundary layer, and  is the coordinate normal to the wall. is the coordinate normal to the wall.The definition of Momentum thickness for incompressible flow is  I read in a post that velocity profile can be obtained by creating a line perpendicular to the surface at the point of interest. and with the help of that line velocity variation can be plotted. I don't know how to plot shape factor in fluent. Can anybody please help me in this regard. |

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Problem in applying Gamma-Retheta transition model | mb.pejvak | Main CFD Forum | 2 | November 13, 2012 11:27 |

| problem in turbulent flow over flat plate with stagnation point | mb.pejvak | Main CFD Forum | 0 | September 12, 2012 22:25 |

| Trans. SST Intermittency Factor and Viscosity Ratio | eishinsnsayshin | FLUENT | 3 | May 23, 2012 04:02 |

| IFStream read float point data problem | liu | OpenFOAM Running, Solving & CFD | 0 | October 24, 2008 13:14 |

| Transition Point shape factors!! please help | Simon c | FLUENT | 0 | March 12, 2006 12:00 |