|

|

|

[Sponsors] | |||||

SolidWorsk Flow Simulation: Rotating region - unnaturally low flow |

|

|

|

LinkBack | Thread Tools | Search this Thread | Display Modes |

|

|

|

#1 |

|

New Member

Marian

Join Date: Jan 2019

Posts: 1

Rep Power: 0  |

Hello everybody

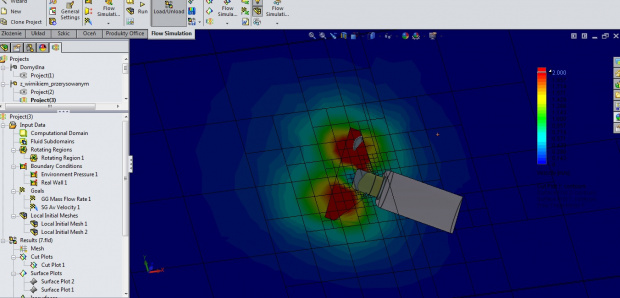

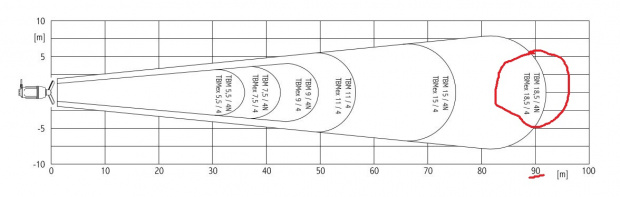

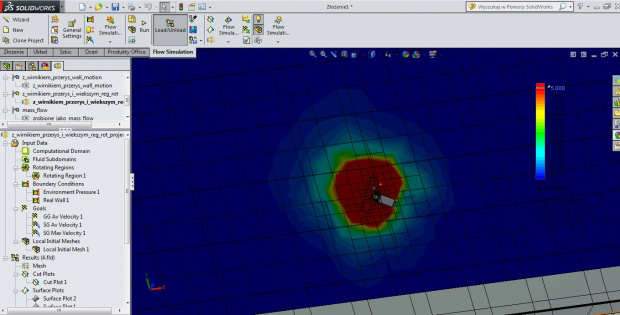

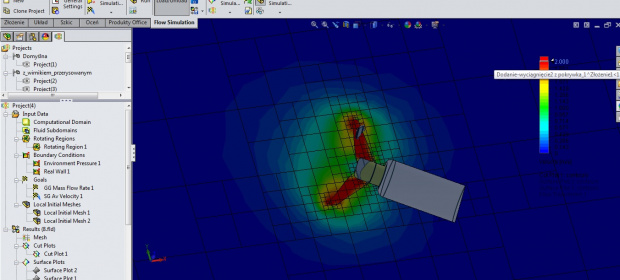

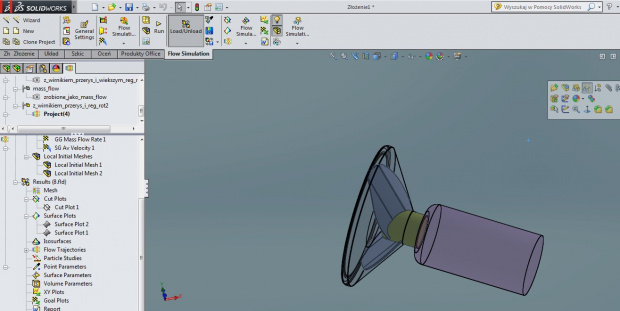

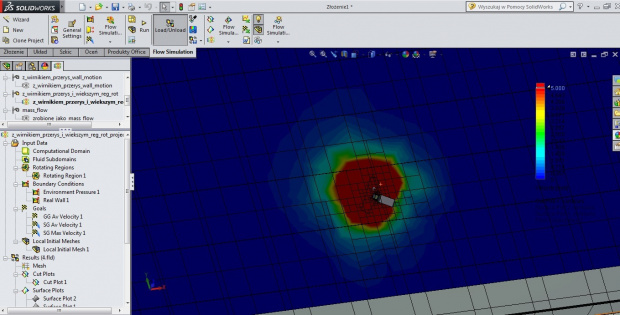

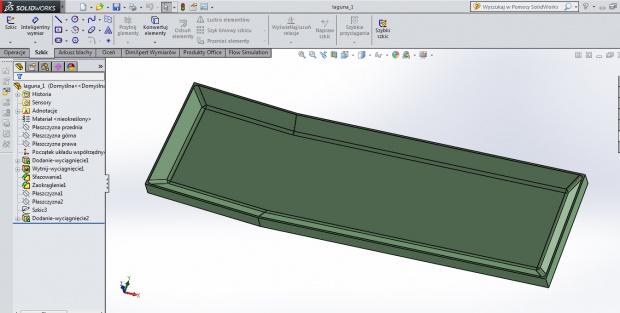

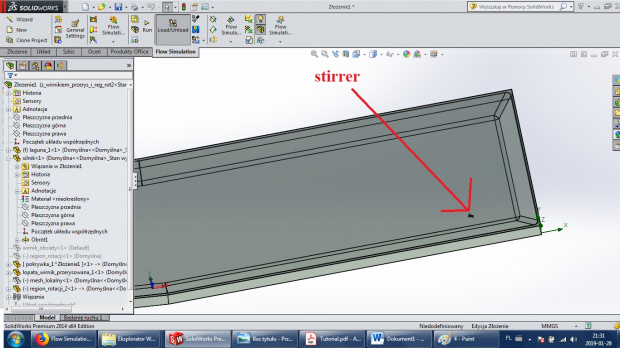

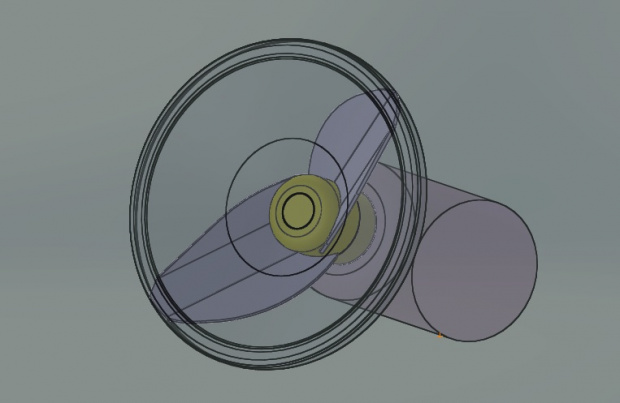

, ,I have problem with rotational region. There is no flow or very very small flow between rotational region and rest of the fluid:  I know, that in real world this stirrer really works, and it should mix fluid in large distance (I've got TBM 18,5 variant, so it should be flow on 90m):  Iíve tried to change rotational region - bigger:   - or smaller:   and there is the same story. and there is the same story.Informations: I have large tank (aprox. 120x35x4m):  and some stirrer (aprox 800 mm diameter):   Initial mesh Iíve tried on levels 1,2,3,4 and 5, with 0,001m min gap and 0,003m wall thickness or without manual these manual gaps and there is the same story. Fluid is water, analysis is internal flow. Solver is working fine etc. Iíve tried also different speeds of the rotor Ė from 300 to 4000 rpm, almost the same story. There is almost no difference if it have local initial mesh area or without it. Anyone know what the problem is? Thank you in advance, Marian - student from Poland |

|

|

|

|

|

|

|

|

#2 |

|

Disabled

Join Date: Jul 2009

Posts: 616

Rep Power: 24  |

Hi Marian,

there are 2 essential problems in your model setup: 1. The rotating region should be a little bigger as you have to consider some cells between the rotor and the rotating region walls. 2. The mesh resolution. Your mesh is "WAY" too coarse. You have to resolve the flow with the mesh. This means you need a fine mesh at the propeller to resolve what is happening on the surface and neat to it as well as the stream leading away from it. It is like telling what the temperature in the northern country is with only one temperature sensor in the middle of the country. It is impossible to know as things change the further you go away from the sensor. The same is with the mesh if you consider each cell being a sensor. If you have only very big cells then the results of what you want to get in the far distance are not accurate as in CFD the flow propagates from cell to cell and if they get too big where you expect a certain flow field, then you cannot resolve that flow field fine enough. With measurements its easier as you measure what nature does, but with CFD you are simulating nature and therefore you need to also resolve it. Your mesh gets very big very fast and does not show that flow you expect because the results diffuse into too big cells. If you expect such a cone-like flow field stretching away from the fan, then use a local mesh like that to resolve that field finer. You can also use adaptive refinement to refine the mesh based on the flow gradients. But it is also best to have a good mesh already to refine on. Simply using the automatic mesh doesn't work in some cases, especially with such dimension jumps from your 0.8m propeller to a 120x35m tank. Even higher RPM will not help as it also diffuses too quickly. Also, if you create images that are this dark, please try to deactivate the lighting, the small light bulb in the toolbar on the right. For 2D plots, the lighting can create very dark images as the light shines from an angle which doesn't illuminate the plot but throws a shadow like in yours. Hope this helps, Boris |

|

|

|

|

|

|

| Tags |

| flow simulation, low flow, problem, rotating region, solidworks |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Low Reynolds no (near rarefied) flow simulation in CFD++ or conventional CFD packages | balkrishan | Main CFD Forum | 0 | February 4, 2018 12:39 |

| Laminar flow simulation in rotating domain | rahulv | CFX | 7 | July 9, 2014 07:19 |

| [blockMesh] Flow domain by BLOCKMESH for plasma induced flow simulation | mukut | OpenFOAM Meshing & Mesh Conversion | 0 | June 2, 2014 07:19 |

| [Other] StarToFoam error | Kart | OpenFOAM Meshing & Mesh Conversion | 1 | February 4, 2010 05:38 |

| transient simulation of a rotating rectangle | icesniffer | CFX | 1 | August 8, 2009 08:25 |