|

|

|

[Sponsors] | |||||

Mesh not converging as expected in a FSI problem |

|

|

|

LinkBack | Thread Tools | Search this Thread | Display Modes |

|

|

|

#1 |

|

New Member

Join Date: Dec 2010

Posts: 8

Rep Power: 15  |

Hello everyone,

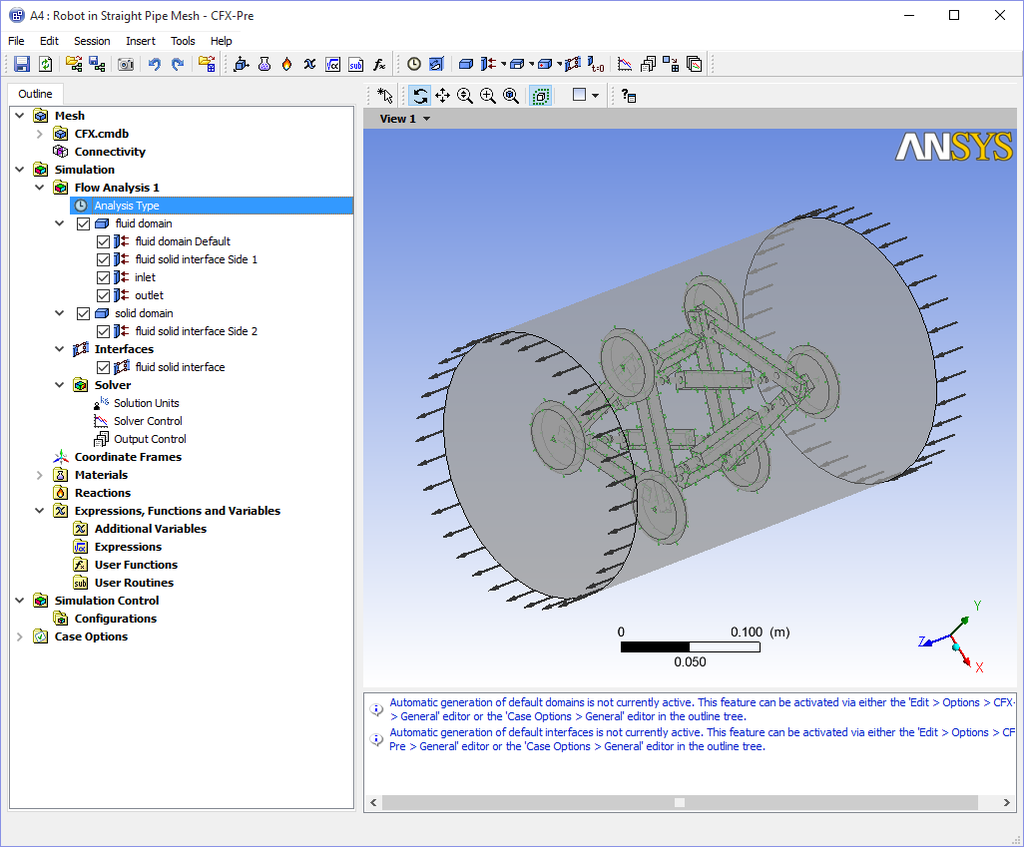

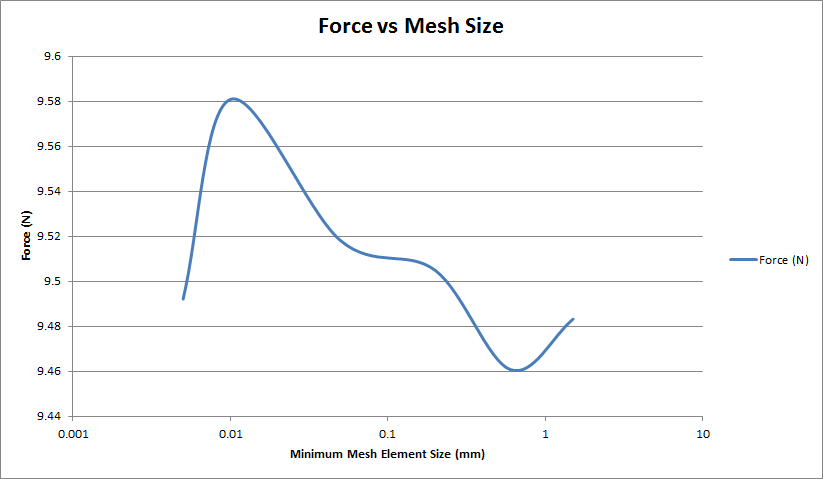

I'm new to the field of CFD and have been using ANSYS CFX to run a simulation whereby I have a solid object in a pipe (a robot) and I'm wanting to simulate the force exerted on the object due to the flow. The model was constructed in Solidworks by positioning the solid object model within the model for the pipe's interior volume. The solid object was then subtracted from the pipe volume model, producing the actual volume occupied by the fluid. This whole assembly was then imported into ANSYS Workbench as a Fluid-Solid simulation, where I defined the fluid and solid regions, the boundary conditions and the fluid-solid interface. After the simulation is run, the force is being calculated using the "force" function of the Function Calculator on the fluid solid interface in a particular axis.  I've got a question regarding the mesh independence study/mesh optimisation. I understand the need to test different mesh sizes and see if the results converge in order to determine the optimal mesh size to use. By default, ICEM CFD is using the Curvature advanced size function, which allows me to specify the minimum element size. If I choose an element size too big (e.g. 3mm) the software will refuse to generate the mesh complaining about mesh quality. I've found that the largest value I can specify for my model is about 2.5mm. I've run the simulation for a range of different Min Size values (1.5mm to 0.005mm) and recorded the total force exerted on the object inside the pipe. Unfortunately, I didn't see any convergence. The results were all very close, with a maximum deviation of 0.78% from the average value (which is certainly good enough for my work). You can see the results in the table below.

I did try and mesh again but without using the advanced size function and just using a fixed mesh size of 1.5mm. This resulting in a huge number of elements and the resulting force was 9.42818N, 0.84% away from the previously mentioned average value. Unfortunately, trying to decrease the mesh size further results in the simulation not running due to the huge amount of elements generated and the large RAM requirements. I also tried using the Curvature and Proximity generator with its default values. This gave me a result which was 9.35803N, 1.57% away from the previously mentioned average. My problem is that because the results aren't converging in the way that would normally be expected, I'm not sure whether the mesh size is optimised or not, and as such, I'm not sure how I'd go about defending these results. I don't know whether the fact that all of the results are within 0.78% of the average (which is perfectly fine for me) would be good enough. I was wondering if someone could shed some light on this, please. Thanks, Amr Last edited by amrbekhit; September 6, 2015 at 13:55. |

|

|

|

|

|

|

|

|

#2 |

|

New Member

Gerard

Join Date: Dec 2014

Posts: 7

Rep Power: 12  |

Did you try much coarser meshes ?

Last edited by squick; September 6, 2015 at 15:48. |

|

|

|

|

|

|

|

|

#3 |

|

New Member

Gerard

Join Date: Dec 2014

Posts: 7

Rep Power: 12  |

Are your results well converged to machine accuracy ?

|

|

|

|

|

|

|

|

|

#4 |

|

New Member

Join Date: Dec 2010

Posts: 8

Rep Power: 15  |

Hi squick,

The coarsest mesh size I could try was 2.5mm. Any larger than that and the mesher complains about the quality of the mesh and refuses to continue. In the results above, I go up to 1.5mm without seeing any convergence. I'm not familiar with the term "machine accuracy", but my initial searches indicate that that is referring to the smallest floating point value that can be represented. According to Wikipedia, a 64-bit double has a machine accuracy of 2.220446e-16, which is very very small. My deviations in force are way above this (Not sure if I've understood this concept correctly!). |

|

|

|

|

|

|

|

|

#5 |

|

Super Moderator

Glenn Horrocks

Join Date: Mar 2009

Location: Sydney, Australia

Posts: 17,870

Rep Power: 144     |

The first question you need to ask is whether an error which could be 1.5% is close enough. For many applications that would be fine and so there is no need to continue.

Mesh sensitivity studies on complex meshes with many mesh controls is difficult, as mesh sensitivity studies are best done when the whole mesh is scaled by the parameter, so both the coarse and fine bits. When you adjust the min mesh size you are probably only changing the mesh size in a small section of the total mesh. That is why many mesh sensitivity studies are done on fixed mesh sizes. As that is sometimes not practical, an alternative is to only change the mesh size in the area of fundamental importance, and leave the remainder of the mesh which does not contribute much to the final result unchanged. This is a compromise, but it can make complex meshes manageable. |

|

|

|

|

|

|

|

|

#6 |

|

New Member

Join Date: Dec 2010

Posts: 8

Rep Power: 15  |

Hi Glen,

Thanks very much for your response and for clarifying. Now I feel more comfortable about the whole process and with the work that I've already done. Thanks again! Amr |

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| [Other] Mesh Importing Problem | cuteapathy | ANSYS Meshing & Geometry | 2 | June 24, 2017 06:29 |

| ParaView for OF-1.6-ext | Chrisi1984 | OpenFOAM Installation | 0 | December 31, 2010 07:42 |

| Icemcfd 11: Loss of mesh from surface mesh option? | Joe | CFX | 2 | March 26, 2007 19:10 |

| How to control Minximum mesh space? | hung | FLUENT | 7 | April 18, 2005 10:38 |

| unstructured vs. structured grids | Frank Muldoon | Main CFD Forum | 1 | January 5, 1999 11:09 |