|

|

|

[Sponsors] | |||||

Low Mach Number Compressible Multiphase Flows |

|

|

|

LinkBack | Thread Tools | Search this Thread | Display Modes |

|

|

|

#1 |

|

Member

Join Date: Sep 2009

Posts: 69

Rep Power: 17  |

Hello everyone,

I am facing some difficulties with simulating compressible multiphase flow in a vessel. This is my case : I am simulating the pressure buildup of gas phase in an enclosed vessel partially filled with liquid. The vessel will have an inlet pipe that pumps gas into the gas cap of the vessel to pressurize it. The pressure builds up to a certain value and an outlet pipe which is initially a wall will be turned into an outlet, whereby the high pressure gas will force the liquid out of the vessel. Before all of this happens, the tank will be empty and a separate inlet pipe (multiphase gas and liquid) will fill the vessel to a desired liquid level before shutting off and allowing the gas pressure in the vessel to build. Note the gas from the inlet will be vented during the liquid fill stage and this vent shuts off during pressure buildup stage. I have mostly dealt with incompressible multiphase flows up until now. I am using an inhomogeneous multiphase model, with properties of the gas defined as ideal gas and the liquid has constant density. Heat transfer is defined to be isothermal. I am running a steady state simulation of the filling stage at the moment to produce an initial solution. So I am not even ttrying to simulate the gas compression stage yet. However, this simulation of mine keeps crashing. From what I can see before it crashes, there are extremely high and unphysical Gas Mach Numbers in the vessel. Pressures in the system are extremely high as well and gas velocities are through the roof. It runs nicely for a while with residuals converging (0.001 ts for 500 iter and then 0.01 ts) before P-Vol starts increasing and fluctuating wildly and then kaboom. I have tried numerous things, including halving the flow rates at the inlet, using the double precision solver, but none seem to have solve the problem. When I turned the whole simulation back into an incompressible simulation however it works like a charm and the tank fills up nicely. So my question is this. Is the inhomogeneous multiphase solver able to handle low mach number compressible flow on only ONE of the continuous phase? Is the turbulence model and hence the boundary layer mesh a big factor in causing the solver to crash? I am using SST Turb Model with Automatic wall function, with yplus less than 200 everywhere so I dont think so. I have read that low mach number compressible flows can be tricky at times. Is this true? I would think that it shouldn't be a problem as ive seen IC engine CFD simulations during the compression stage done using CFX. Does meshing play a big factor in the behaviour of the solver? My reading tells me no and a finer mesh can sometimes work against you for compressible flow in terms of solver convergence. And Lastly...What is going on!!!!  Hope some of you guys can help me out Cheers DarrenC |

|

|

|

|

|

|

|

|

#2 |

|

Senior Member

Edmund Singer P.E.

Join Date: Aug 2010

Location: Minneapolis, MN

Posts: 511

Rep Power: 21  |

Quick suggestion. Are you using an incompressible model for the liquid? Try making that slightly compressible.

|

|

|

|

|

|

|

|

|

#3 |

|

Super Moderator

Glenn Horrocks

Join Date: Mar 2009

Location: Sydney, Australia

Posts: 17,871

Rep Power: 144     |

This sounds like an FAQ: http://www.cfd-online.com/Wiki/Ansys...gence_criteria

|

|

|

|

|

|

|

|

|

#4 |

|

Member

Join Date: Sep 2009

Posts: 69

Rep Power: 17  |

Singer : No my fluid is incompressible (i.e constant density). I can try making the fluid compressible by relating the density to pressure via the bulk modulus of my liquid but I am not sure if the differences will be noticable. I could be wrong .....

. Is there a specific reason why you think a compressible fluid will help? . Is there a specific reason why you think a compressible fluid will help?Ghorrocks : Ahhhh the Convergence FAQ. I will have a detailed rundown of it. Will let you know how I go. In the meantime the first question of mine still bugs me (i.e whether you can have one compressible and one incompressible continuous phase in your inhomogeneous multiphase simulation). From what I see so far on the simulations people do especially in multiphase pumps and IC engines this shouldnt be a problem. But I haven't actually pored through the maths yet to understand it in detail. Perhaps you could shed some light on this? Thanks guys for your input. Keep em coming!! Cheers DarrenC |

|

|

|

|

|

|

|

|

#5 |

|

Super Moderator

Glenn Horrocks

Join Date: Mar 2009

Location: Sydney, Australia

Posts: 17,871

Rep Power: 144     |

I have done simulations with a incompressible continuous phase and a fully compressible disperse phase for cavitation modelling. But that particular model never progressed far enough for me to fully validate it so I cannot be sure everything was working as required.

But I think it can be done. |

|

|

|

|

|

|

|

|

#6 |

|

Senior Member

Edmund Singer P.E.

Join Date: Aug 2010

Location: Minneapolis, MN

Posts: 511

Rep Power: 21  |

I have done just a few simulations like you describe.

Making the liquid slightly compressible allows it to transfer pressure changes more gradually through that media and helps out convergence. When I used a fully incompressible liquid, my solution would go for a bit, then the pressure field in the liquid would go haywire. |

|

|

|

|

|

|

|

|

#7 | |

|

Member

Join Date: Sep 2009

Posts: 69

Rep Power: 17  |

Quote:

On another note I am not sure if this phenomena is somehow related to some really violent liquid movements inside my vessels that I have seen of late using inhomogeneous multiphase. Before this I was doing some 3-phase (oil,water,gas) inhomogeneous multiphase flows using all incompressible continuous fluids. These simulations were both transient and steady state simulations. I posted the problem in a thread I started before and havent really been able to fix as the problem as it is intermittent (appears in some but not all runs when runs are repeated) http://www.cfd-online.com/Forums/cfx...imulation.html Basically when slow filling the separator vessel with liquid, the liquid in the vessel will suddenly slosh around violently and this will sometimes cause the solver to crash. Residuals, pressures and mass flows will suddenly spike for 1-2 iterations and if that dosent crash the simulation will die down to normal again. Since you have had the experience of performing this style of simulations, have you experienced anything like that before and if so do you know what is causing them? Cheers DarrenC |

||

|

|

|

||

|

|

|

#8 |

|

Senior Member

Edmund Singer P.E.

Join Date: Aug 2010

Location: Minneapolis, MN

Posts: 511

Rep Power: 21  |

You are vastly overstating my experience with these types of models

. . Go with the slightly incompressible model for the liquids. If it works, I will accept the genius label. If it doesn't work.... |

|

|

|

|

|

|

|

|

#9 |

|

Super Moderator

Glenn Horrocks

Join Date: Mar 2009

Location: Sydney, Australia

Posts: 17,871

Rep Power: 144     |

As I said in my previous post, the first thing to check regarding the spurious flows is your convergence. Free surface models generate small spurious flows, the question is whether your numerical model is stable enough to damp them out. If it is not stable enough they will grow, eventually becoming significant flow features - which are completely incorrect.

So rerun the simulation with tighter convergence and see if that changes anything. |

|

|

|

|

|

|

|

|

#10 |

|

Member

Join Date: Sep 2009

Posts: 69

Rep Power: 17  |

Hi Glenn,

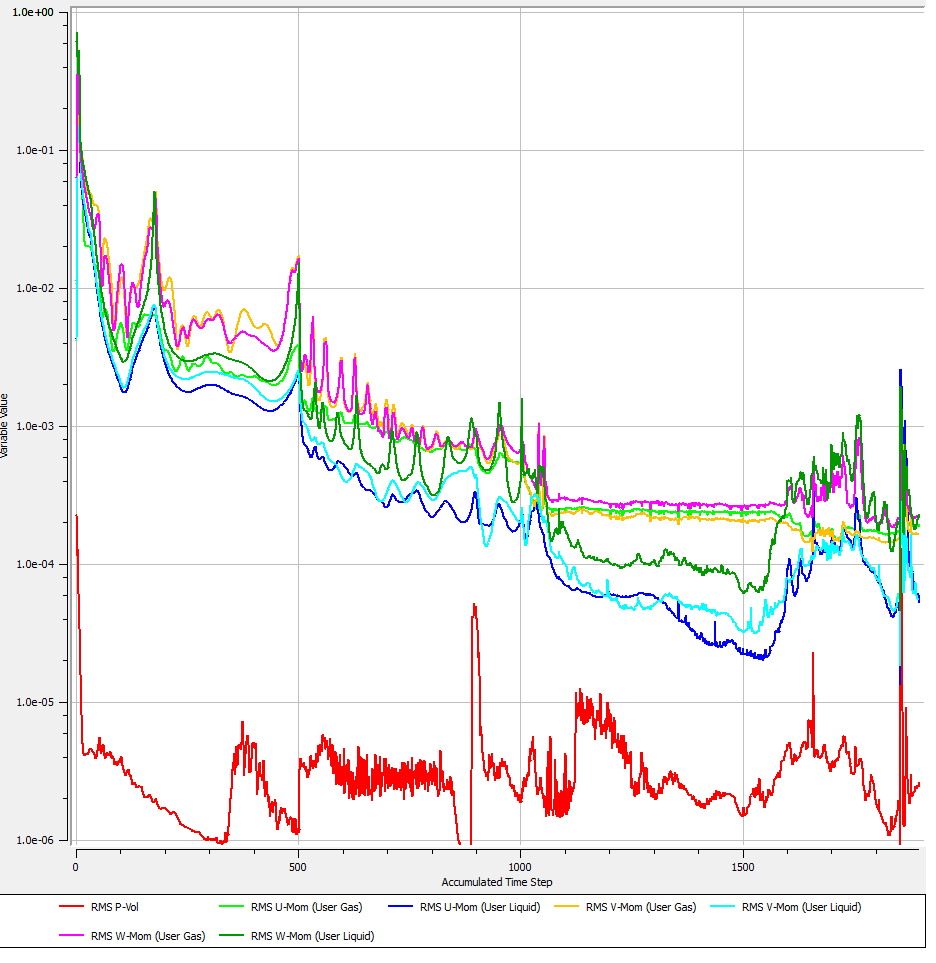

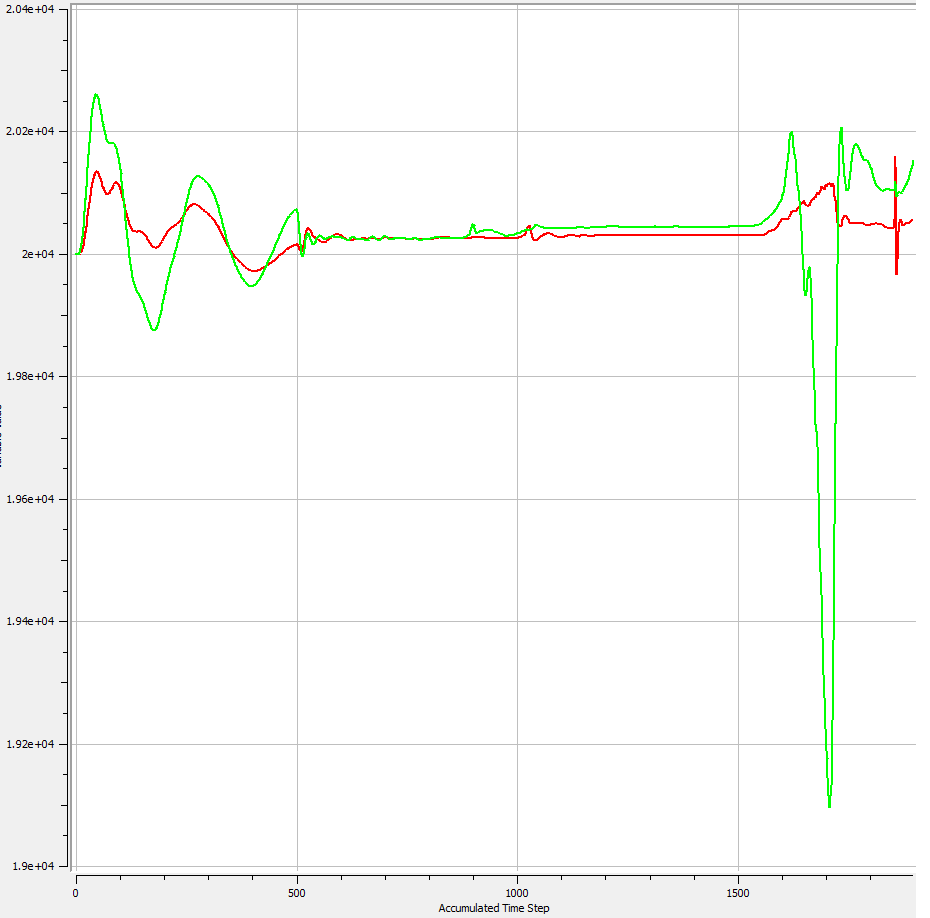

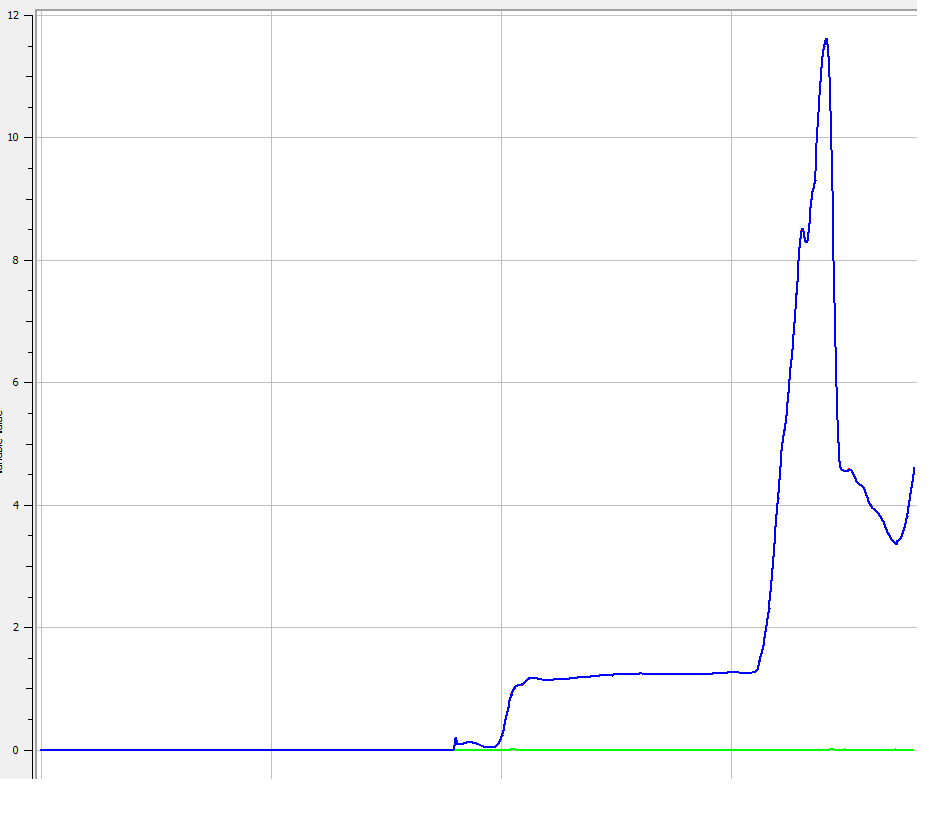

I have done a little bit more work on this model. First thing I did was to run it with a finer mesh. The solver did run much longer than the previous model (approx an additional 700 iterations). The gas phase momentum residuals plateau to a (maximum) steady value of approximately 2 x 10^-4. The liquid phase momentum residuals are lower than the gas phases, and continue to decrease, albeit quite slowly. After a few hundred iterations (of the gas phase residuals plateauing) the residuals start to climb again, then oscillate wildly and then the solver crashes. Below is a screenshot of the residuals.  In this simulation, timestep was changed at 500 iter (0.001 -> 0.01) and 1000 iter (0.01 -> 0.1). It is rather hard to pinpoint what is causing the solver to crash from the result files as the change in conditions happens real sudden. Following are some monitors I put in my simulation.  This figure shows pressure probes in 2 faces inside the vessel. As you can see the pressure stabilises from 500-1500 but suddenly fluctuates wildly after that.  This figure shows the mass flow of a pipe inside the vessel (there are 2 vessels. Top and bottom. Liquid flows from the inlet to the top vessel thru this pipe to the bottom vessel) . As you can see the liquid mass flow stabilises from 1000-1500 (Liquid has not reached this pipe from 0-1000) but suddenly shoots up after 1500. All this happens while the gas and liquid inlets going into the top vessel remains constant. Could this be the small instabilities that you mentioned? If so, would it be wise to refine the mesh at the interface of the liquid/gas phases to better capture the interphase region? Is it normally highly essential to get the mesh in this interphase region really fine for solver stability? And also in terms of dampening the instabilities as you mentioned, I would assume you mean numerically? (i.e lower order numerical schemes) Also when you mention 'tighter' convergence, do you mean having the convergence criteria for the residuals set to a lower thereshold? In my case I set the convergence criteria to be 10^-4 but not all my residuals will hit this thereshold as shown in the residual plot. Hope you (or anyone else for that matter) could shed some light on this. Thanks again! Cheers DarrenC |

|

|

|

|

|

|

|

|

#11 |

|

Super Moderator

Glenn Horrocks

Join Date: Mar 2009

Location: Sydney, Australia

Posts: 17,871

Rep Power: 144     |

I would have a look at the results file in the region of iteration 1700 until it crashes. See if you can identify the source of the sudden weirdness. It could be real (for instance the fluid level reaches a critical point) or it could be spurious (a minor instability grew until it became a major disturbance).

Regardless of the results file you should improve the numerical stability of this simulation. The more complex the simulation the more important this is - and yours is complex. * Use double precision numerics * Use a smaller time step * Use a transient model, not steady state * (this is the most important one) - redo you mesh to improve mesh quality Note that refining your mesh makes the simulation less numerically stable. It is a common mistake to think that a finer mesh is more stable. |

|

|

|

|

|

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| AMI interDyMFoam for mixer | danny123 | OpenFOAM Running, Solving & CFD | 4 | June 19, 2013 05:49 |

| Fluent 12.0, Low Reynolds Number Flows | anandvksin2003 | FLUENT | 1 | January 26, 2010 06:16 |

| high mach number, and multiphase | AdN | FLUENT | 0 | April 13, 2006 10:40 |

| acoustics and low mach number | George | Main CFD Forum | 42 | November 3, 2005 07:05 |

| Low Re number flows | Wu Chun-Kai | Main CFD Forum | 17 | July 1, 1999 21:24 |