|

|

|

[Sponsors] | |||||

|

|

|

#1 |

|

New Member

Daniel

Join Date: Mar 2015

Posts: 3

Rep Power: 11  |

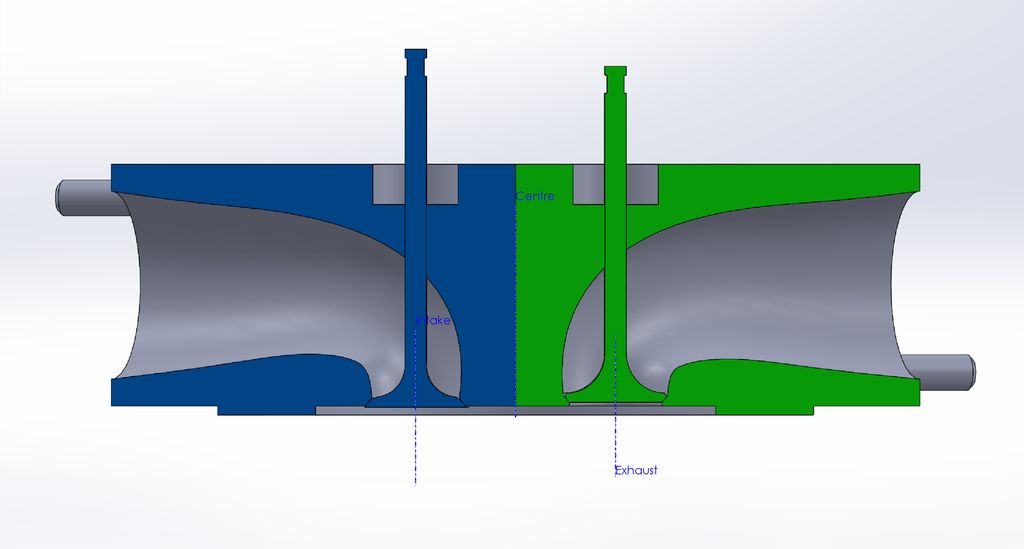

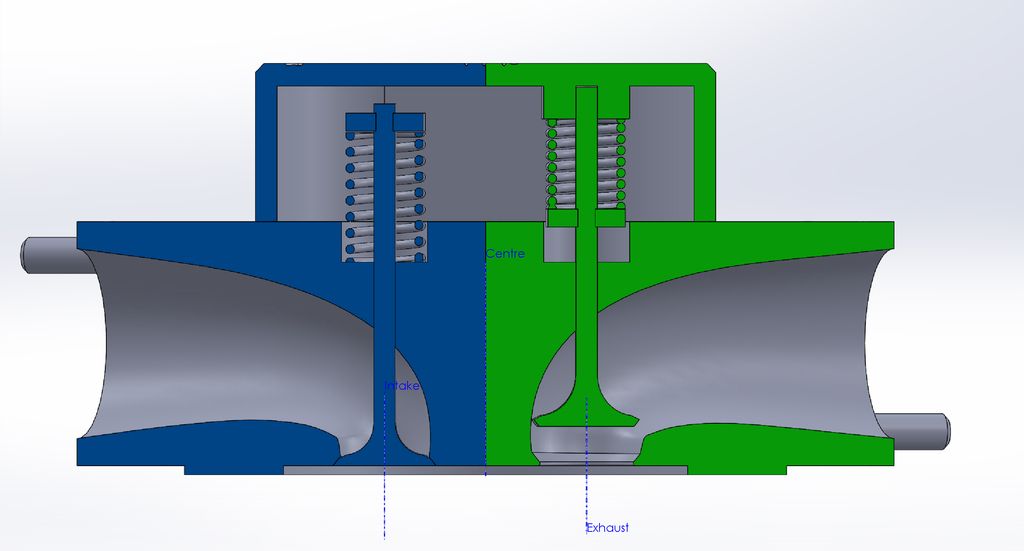

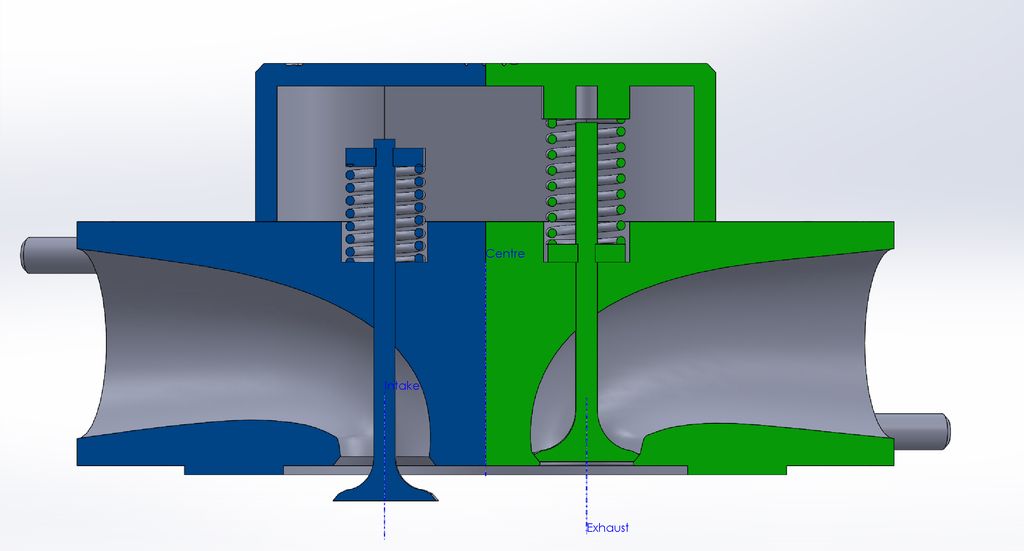

I am currently carrying out work for my dissertation but have run into a couple of problems with flow simulations. I am researching the feasibility of converting a v-twin motorcycle engine into a supercharged single cylinder using the other cylinder as a piston pump to compress the intake air.

The most important component of this system will be the cylinder head on the piston pump. I am looking at ways to incorporate automatic valve instead of mechanically actuated valves. Hopefully relying on spring closed valves that open due to a pressure difference on either side. I have tried over the past week to simulate this in various software packages but mainly Ansys IC engine. Yet to succeed i am starting to wonder if this kind of simulation is possible.  I am hoping to carry out a transient analysis of the system, modeling the pressure change within the cylinder, the affect of spring constants and eventually plot volumetric efficiency against engine speed and pressure ratio. Any help in determining if this is possible would be highly appreciated, i need to know if I'm wasting my time so i can continue with other aspects of the project. Cheers, Dan. |

|

|

|

|

|

|

|

|

#2 |

|

New Member

Join Date: Jan 2015

Posts: 21

Rep Power: 0  |

Hi Daniel

I think you need to "frame" the problem before to start with 3D simulation. Try to use 1D simulation software (AMESim or GTPower). Pay attention: in your drawing the exhaust valve seat is reversed. |

|

|

|

|

|

|

|

|

#3 |

|

New Member

Daniel

Join Date: Mar 2015

Posts: 3

Rep Power: 11  |

I've got access to Ansys, Matlab and Ricardo. I have built a model of the entire engine on Ricardo but required more data for just the piston pump section.

Currently it is only the piston pump that i am focusing on and the means to which that i can control the flow in and out. I wanted to move away from mechanically actuation and instead rely on pressure to actuate the valves, hence the reverse valve and valve seat for the exhaust. Would 1-D simulation allow me to incorporate the pressure actuated spring valves?

|

|

|

|

|

|

|

|

|

#4 |

|

Member

Ethan Doan

Join Date: Oct 2012

Location: Canada

Posts: 90

Rep Power: 14  |

Im no too familiar with GT but I can tell you AMEsim has very good capabilities for engine modelling and you will be able to control the valves aswell. In the AMEsim IFP libraries you can even couple the 1-D code with a build in 3d combustion solver, alternativley you can choose to couple the AMEsim code with any commercial solver to handle the combustion analysis if you deem the 1-D approach to combustion unsatisfactory. I work with AMEsim alot feel free to message me if you need more info.

|

|

|

|

|

|

|

|

|

#5 |

|

New Member

Join Date: Jan 2015

Posts: 21

Rep Power: 0  |

This is the TOOLS available in AMESim environment: of course you can work inside AMESim even for the engine modelling.

We use AMESim for injector simulation and the model is very realistic compared to the experimental data and 3D fluent-CFX simulation. |

|

|

|

|

|

|

|

|

#6 |

|

New Member

Daniel

Join Date: Mar 2015

Posts: 3

Rep Power: 11  |

Thank you for the useful responses. I know now that the best way to simulate it is using 1D, i'm not sure why i was even considering 3D at this stage. It's unlikely that I will have adequate time to learn amesim before my dissertation is due in but cheers for the suggestion. I would like to continue this project so will likely learn to use the software.

|

|

|

|

|

|

|

|

|

#7 |

|

Member

Ethan Doan

Join Date: Oct 2012

Location: Canada

Posts: 90

Rep Power: 14  |

AMEsim is pretty easy to learn i was up to speed with my work in about 2 weeks having only 3D simulation experience before. For your application a number of tutorials exist you can use them as templates. by copy and pasting the submodels between the different tutorials and changing some parameters you should be able to get some useful results in very little time. How much time do you have? I would assume more then a few weeks if you were originally planning on a full 3d combustion simulation. i would be willing to help. Good luck with the rest of your degree!

|

|

|

|

|

|

|

| Tags |

| cylinder, engine, formula student, piston pump |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Drag force coefficient too high for a flow past a cylinder using komega sst | Scabbard | OpenFOAM Running, Solving & CFD | 37 | March 21, 2016 17:16 |

| single injection of gasoline to cylinder filled with air | maczaj | FLUENT | 0 | January 2, 2015 09:37 |

| Single annulus concentric cylinder | Satya prakash | Main CFD Forum | 0 | February 3, 2011 01:40 |

| [blockMesh] Specifying boundary faces failes in blockMesh | blaise | OpenFOAM Meshing & Mesh Conversion | 0 | May 10, 2010 04:56 |

| drag coeffecient of a single cylinder | Allan | FLUENT | 4 | February 3, 2004 11:46 |